A variety of shellers and hullers are available for processors of grains, beans, nuts, and pulses. To maximize the effectiveness and efficiency of these machines, it’s important to choose the right equipment and settings for your specific needs, use only high quality, properly dried product, and follow all manufacturer’s instructions for operation and maintenance. In this article, we’ll look at several types of shellers and hullers and how to get the most out of them.

Impact Hullers

Impact hullers remove the hulls from products such as oats, sunflower seeds, hemp, spelt, einkorn, millet, and buckwheat by using centrifugal force to impact the grains or seeds against a hard surface. Inside the centrifugal wheel, the grains or seeds are aligned and thrown against the impact ring. Impact hullers often feature adjustable impact rings, which may be available in various materials to accommodate different types of grains.

Cylindrical Shellers

Cylinder shellers are used to shell or debran grains and pulses including wheat, durum, barley, millet, sorghum, peas, chickpeas, and lentils. They work by abrading the product against abrasive discs to remove the hulls or bran. The product is fed into the chamber via a feed screw and discharges through an adjustable counter-pressure plate. Removed bran or husks are channeled through a perforated screen using aspiration, which both cools the product and helps remove dust and particles.

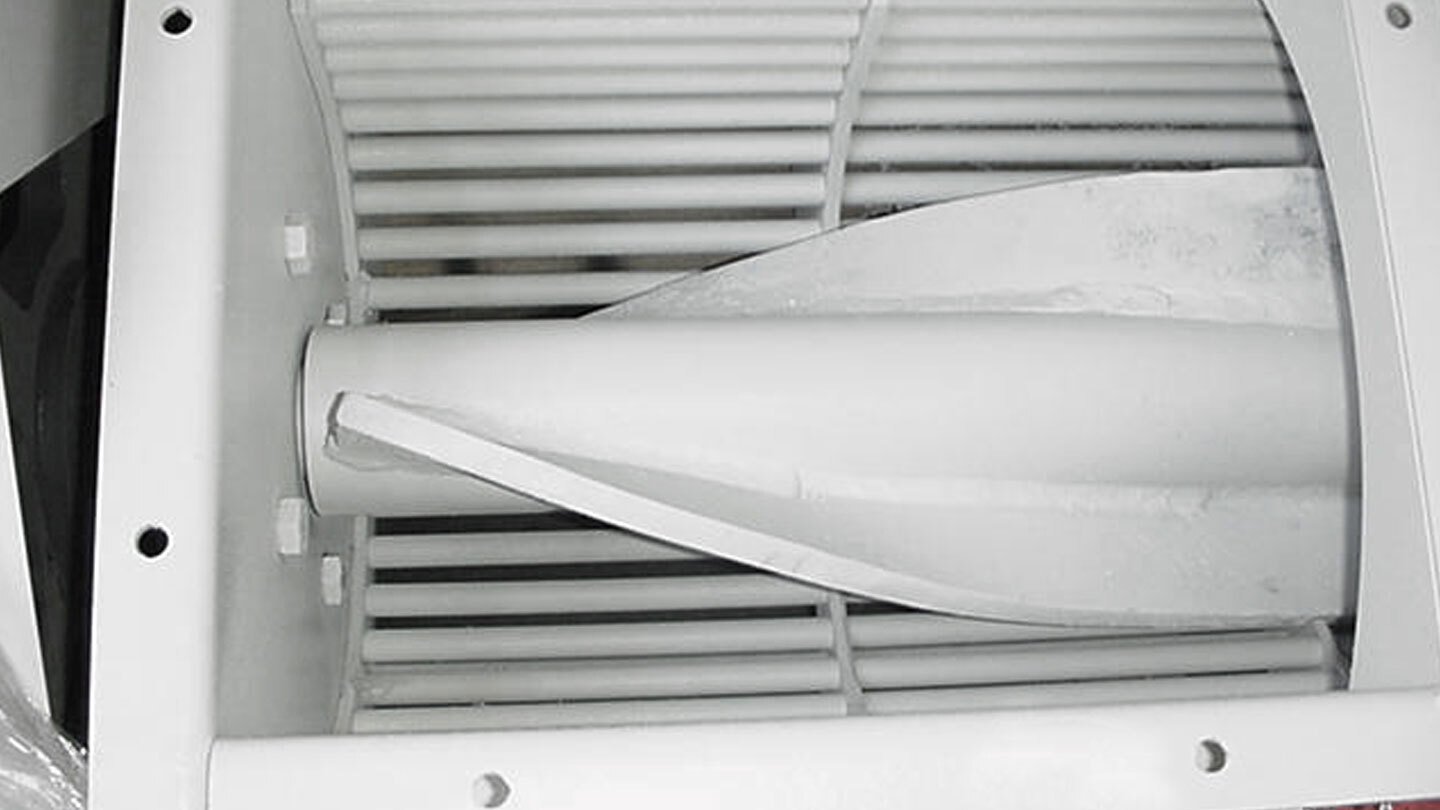

Conical Shellers

Ideal for cereal grains and pulses, conical shelling machines use adjustable conical stones to remove hulls gently yet effectively and can also treat grain surfaces. Depending on the setting chosen, the sheller can remove husks, bran, and impurities.

Roll Shellers

Roll shellers are a great solution for all types of rice. These units use rubber rolls to remove hulls. Rubber roll shellers are especially useful when there is a need for careful, high capacity yet cost-effective shelling.

Getting the Most Out of Your Equipment

Once you’ve selected the right type of equipment for your shelling or dehulling needs, be sure to choose products that have a reputation for durability, performance, and cost effectiveness. Prior to operation, follow these tips:

- Read and understand all manufacturer’s operating instructions, including recommendations for personal protective equipment. This will help ensure you’re using the machine as safely and effectively as possible.

- Use the appropriate settings and speed for the product you’re processing. If not specified by the manufacturer, identifying these may require some experimentation.

- Pre-sort and appropriately clean and dry the product before introducing it into the machine. Debris or nonconforming product could hinder efficiency or damage the machinery.

- Select high quality product to maximize machine efficiency and minimize waste.

- Keep the machinery clean and follow all manufacturer’s maintenance guidelines. Debris can cause clogs, increasing processing time and hurting your operation’s efficiency.

By following these tips, you can optimize efficiency, increasing processing times and yields while reducing waste.

Bratney specializes in helping agricultural processors achieve high quality standards while meeting global demands for their products. Serving clients since 1964, our core values include safety, innovation, quality, and outstanding service. We proudly offer Schule shelling and dehulling machines. Below are some of the features and benefits these quality products offer:

Schule Impact Huller

- Designed to achieve high hulling capacities with minimal breakage

- Variable speed impeller allows for user optimization

- Impact rings automatically adjust (optional), allowing for a longer service life, and can be replaced in minutes without tools

- Impact rings available in stone, steel, and specialty plastics

- Can process up to 3,300 pounds (1,500 kg) per hour of sunflower seeds for bakeries and up to 11,000 pounds (5,000 kg) per hour for oil uses

Schule Cylindrical Shelling Machine

- Adjustable counter-pressure plate

- Fan cools machinery during operation while removing dust and debris (application specific)

- Adjustable intensity

- User friendly

- Easy maintenance

Schule Conical Shelling Machine

- Gap between abrasive discs and the perforated screen can be adjusted by operator to the appropriate intensity for the product, optimizing both efficiency and rotor life

- Fan cools machinery during operation while removing dust and debris (application specific)

- Easy to use and maintain

- Gentle, efficient shelling

Schule’s Rubber Roll Sheller

- Gentle shelling at high capacities

- Can process up to 13,000 pounds (6,000 kg) of rice per hour (depending on variety)

- Fan-cooled rollers for extended life

- Low operating costs

By choosing the right high-quality equipment for your processing needs and following proper operation procedures, you can optimize your equipment, reduce downtime and maintenance costs, and ultimately improve your bottom line. To learn more, browse our blog!