Agricultural plants begin life as fragile seeds that must be handled with meticulous care. Each step of the seed conditioning process is critical to...

Palletizing and De-Palletizing Machinery

Enhance safety and productivity with automatic palletizing and depalletizing systems provided by the premier packaging equipment manufacturer, Concetti.

-

Robotic Palletizers

-

Hybrid-Robotic Palletizers

-

High-Level Palletizer

-

Low-Level Palletizer

-

Bag in Box Palletizer

-

Case Palletizer

-

Robotic De-Palletizer

Robotic Palletizers

Robotic palletizer machines provide automation and flexibility in a compact package. Robotic palletizers can stack many different products, produce any pallet pattern, and overlap bags. Robotic palletizer machines can be configured for simple, single pallet applications or with full automation to palletize products from several bagging lines to one or more pallets.

Technical Features

- Fully Automatic, recipe-driven changeover

- Rate: up to 1,200 bags/hour

- Bag Weight: Up to 110 lbs.

- Flexible, stack bags, bundles, bales, and boxes

Key Benefits

Robotic palletizers have a high level of accuracy and maneuverability which makes it easy for bags to be placed in any programmed palletizing pattern. This machine removes safety hazards from workers manually palletizing and increases the speed and consistency of the packaging process.

Package Types

- Bags

- Bundles

- Bales

- Boxes

Hybrid-Robotic Palletizers

Concetti manufactures an innovative four-column palletizer, the original hybrid-robotic palletizer, combining the flexibility of a traditional robotic palletizer with the speed and perfect pallet shape of a high-level palletizer machine. It is the ultimate combination of high-speed palletizing and the highest quality pallet stack available.

Technical Features

- Fully Automatic, recipe-driven changeover

- Rate: up to 1,200 bags/hour standard, up to 1,800 bags/hour with double pick

- Bag weight: Up to 110lbs.

- Overlapping layer patterns

- Layer squaring

- Layer compression

Key Benefits

This four-column palletizer seamlessly handles bags that are not completely filled or contain aerated or powdery material that is otherwise often difficult to stack. Its flexibility and speed are why customers choose this model 10:1 over other robotic palletizer machines.

Package Types

- Bags

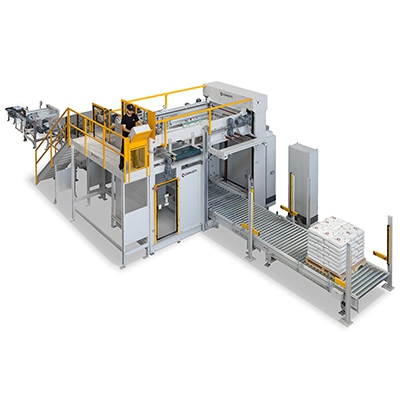

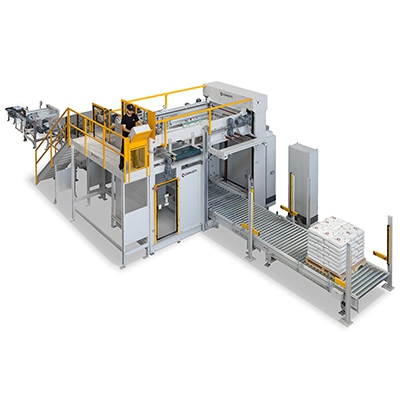

High-Level Palletizer

High-level or push-type palletizer machines provide unmatched speed, up to 50 bags per minute, with extremely square and flat layers producing stable and perfectly square pallet loads. High-level robotic palletizer machines are well suited for almost any type of bag and can also stack bales. High-level palletizer machines are also very simple, requiring very little maintenance.

Technical Features

- Fully Automatic, recipe-driven changeover

- Rate: up to 3,000 bags/hour

- Bag weight: Up to 110lbs.

- High speed

- Layer Squaring

- Layer Compression

Key Benefits

Package Types

- Bags

- Boxes

Low-Level Palletizer

Low-level robotic palletizer machines work well in applications requiring medium speeds, up to 1,000 bags per hour. The low-level palletizer utilizes squaring plates and layer top compression to produce stable and perfectly square pallet loads.

Technical Features

- Fully Automatic, recipe-driven changeover

- Rate: up to 1,000 bags/hour

- Bag weight: Up to 110lbs.

- Layer squaring

- Layer compression

Key Benefits

Package Types

- Bags

- Boxes

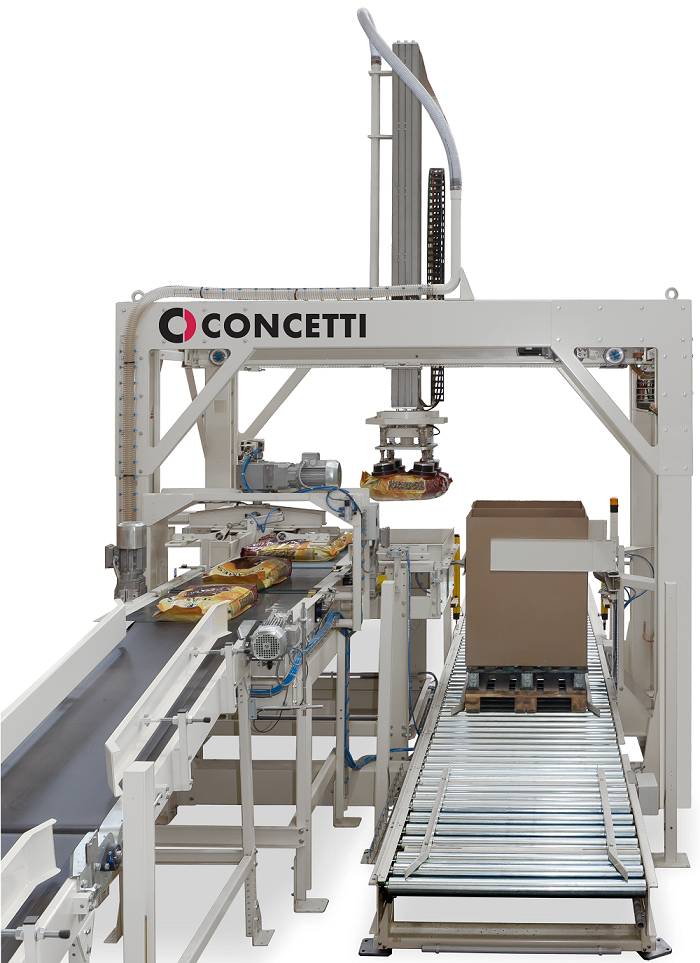

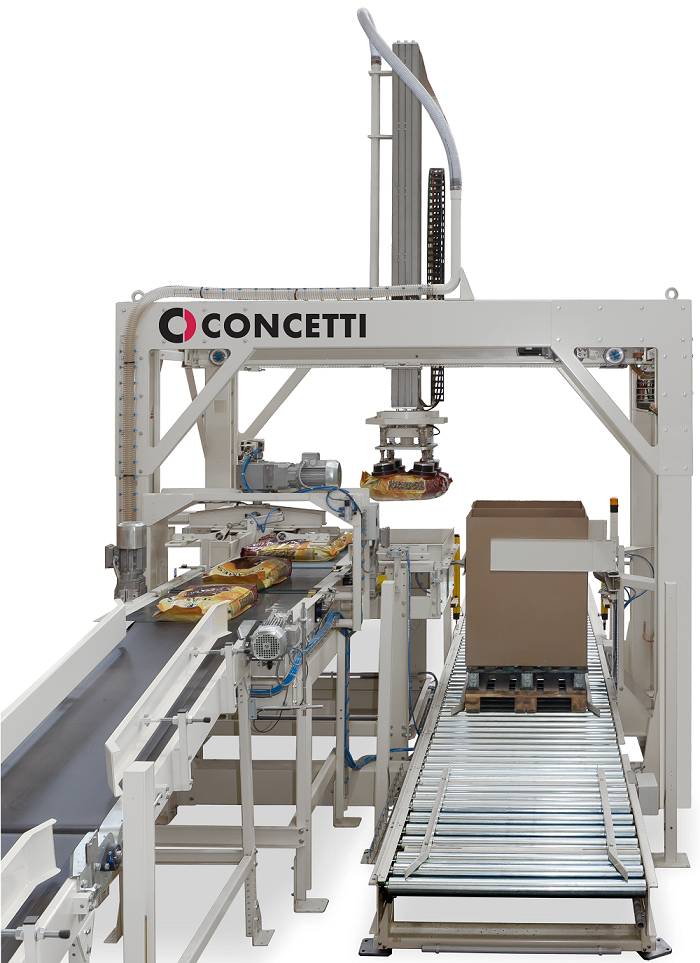

Bag in Box Palletizer

The automated Gantry palletizer machine is extremely flexible and requires very little floor space. This robotic palletizer machine can stack a wide range of products including bags, boxes, trays, and bundles and can also place products into pre-made display cartons or shipping boxes. The compact footprint makes it well suited for tight spaces.

Technical Features

- Fully Automatic, recipe driven changeover

- Rate: up to 1,800 bags/hour

- Bag weight: Up to 110lbs.

- Stack bags on pallets or Into retail display boxes

Key Benefits

Package Types

- Bags

- Boxes

Case Palletizer

Robotic case palletizer machines stack cases and cartons onto pallets and pre-formed trays. These systems can be equipped with vacuum and servo-adjusted end tooling to place the product, slip sheets, and interlayer sheets. Automated carton formers can be integrated upstream for a truly automated carton palletizing system.

Technical Features

- Fully Automatic, recipe-driven changeover

- Rate: up to 1,200 boxes/hour

- Stack cartons and boxes

Key Benefits

Package Types

- Boxes

- Cases

Robotic De-Palletizer

Robotic de-palletizing systems provide automation and efficiency by de-palletizing bags, boxes, or cartons onto outfeed conveyors for ensuing production steps. Advanced end-tooling options are designed for each specific application, ensuring the de-palletizer works flawlessly.

Technical Features

- Fully Automatic, recipe-driven changeover

- Rate: application-specific

- Bag weight: Up to 55lbs.

Key Benefits

Package Types

- Bags

- Boxes

Let's Talk

We want to help you find the right fit for your next palletizing system. Reach out to our team to discuss your needs so we can help you discover the right equipment for you.

Talk to a RepResources

Seed treatment is a cornerstone of modern agriculture. It enhances crop productivity, ensuring farmers get the most out of every seed. By leveraging...

Contact Us

We’re here to answer any questions or discuss how we can help you with your next project or equipment needs.